Social

Supply Chain Management (Procurement)

Procurement Policy and Supplier Criteria

The Mitsubishi Electric Group ensures fair and impartial selection and evaluation of business partners in Japan and overseas by providing an explanation of the Group's Purchasing Policy and CSR Procurement Policy (Sustainability Procurement Policy), and requesting business partners' understanding of these policies. By ensuring proper evaluation of suppliers based on selection and evaluation criteria established by the Group, procurement risks are also mitigated along the supply chain.

The Group’s criteria for evaluating business partners include not only quality, cost, delivery schedules and services, but also initiatives in response to environmental regulations and sustainability initiatives. As a basic policy, the Group preferentially procures materials from suppliers who rank high in a comprehensive evaluation.

Our Purchasing Philosophy

Mitsubishi Electric purchases a wide variety of materials and components from both Japanese and overseas markets. We recognize our corporate responsibility and are eager to provide business opportunities for the communities in which we operate.

1. Easy Access and Equal Opportunity

To guarantee our customers the highest-quality products, we are constantly searching for new suppliers. We encourage business partners from all over the world, regardless of size, to contact us about submitting a quotation. The decision to embark on a new business relationship is made after careful consideration of three major factors: product price, product quality, and delivery performance. To ensure continued high quality and efficiency, we periodically review our relationships with our partners.

2. Mutual Prosperity

We believe in long-term relationships built upon understanding and trust. This will allow the participation of our business partners during the product development stage, paving the way for mutual prosperity.

3. Ecological Soundness

We are interested in the materials and manufacturing processes used by our suppliers. Because we value the environment, we buy only ecologically sound products. Our mission is to satisfy the needs of people around the globe. To meet their growing expectations, we must widen and strengthen our affiliations with companies all over the world. We are seeking cooperation, not just business, and are looking for potential partners who are willing to join us in our drive toward global prosperity.

CSR Procurement Policy

We carry out material procurement activities in line with our "CSR Procurement Policy," which was established in 2007.

We have also established the CSR Procurement Guidelines in 2018 to widely disseminate Mitsubishi Electric’s sustainability policies and matters for compliance by our business partners. We are approaching all business partners to verify their agreements to promote procurement activities in line with the guidelines.

- Compliance with domestic and foreign laws/regulations and social standards

- Ensuring compliance with laws and regulation

- Respecting human rights and prohibiting discrimination, child labor, and forced labor

- Creating proper work environments and giving consideration to safety and health

- Assurance of quality and safety of products and services

- Environmental considerations

- Procuring materials with less negative impact on the environment

- Ensuring strict management of harmful chemical substances based on an environmental management system

- Promotion of fair trade based on corporate ethics

- Practicing honest trade on fair and equal footing, based on laws/regulations and agreements

- Ensuring strict management and safeguarding of information by establishing an information security system

- Thorough elimination of fraudulence, bribery, and other such conduct that violates corporate ethics

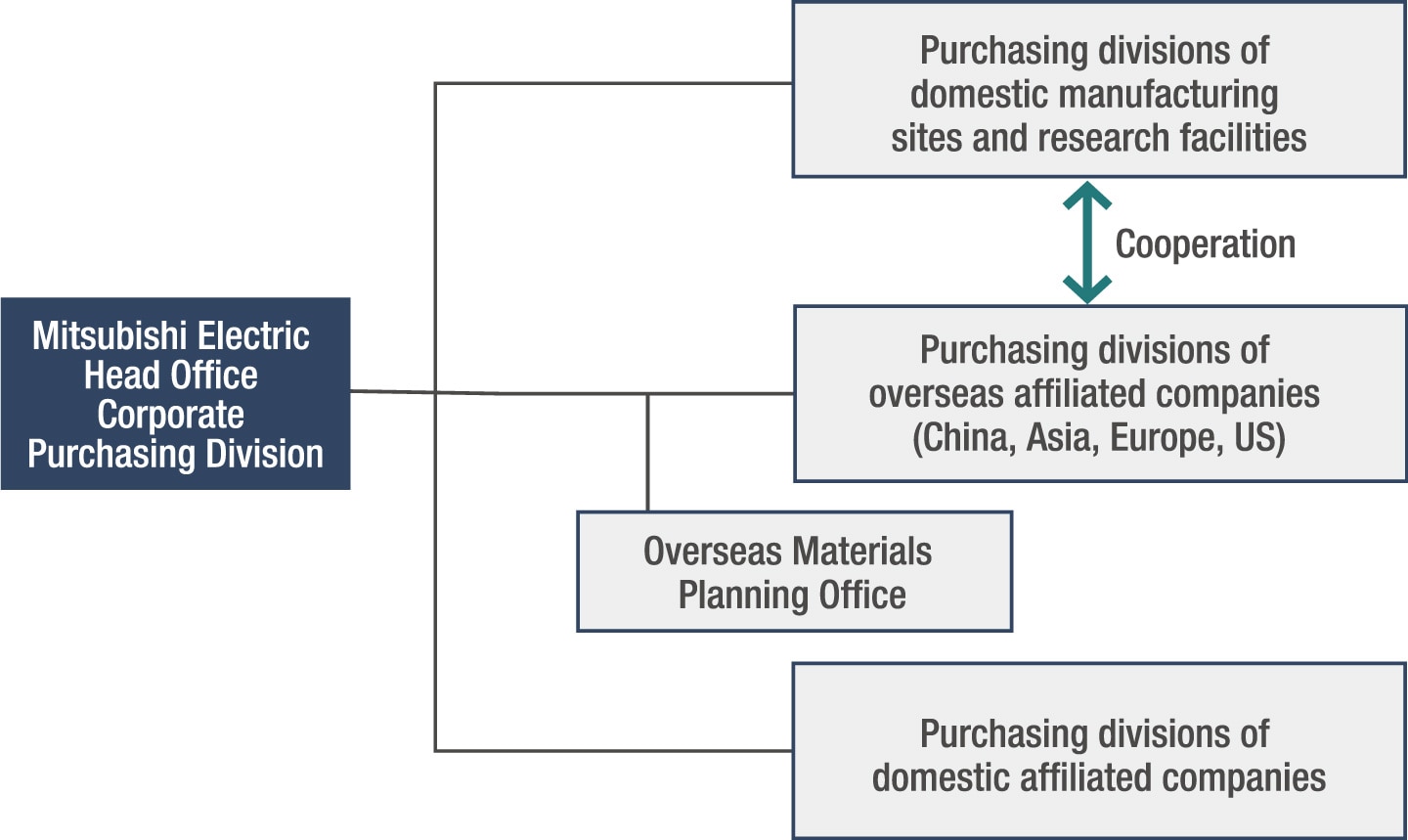

Framework for Promotion of Procurement Supply Chain Management

Under globally sustainable procurement, target costing and cost co-creation by enhancement of partnership (G-STEP) strategy toward strengthening the purchasing structure, the Mitsubishi Electric Group aims to achieve the lowest cost ratio ever starting in fiscal 2021. In this effort, we will develop and promote the following measures with the following aim: "We will contribute to the realization of sustainability through all corporate activities. By doing so, we will make further efforts to enhance economic and social value so as to raise our corporate value," which is the Group’s business goal, through sustainable and stable procurement. In cooperation with the Materials Planning Office in regional corporate offices in China, Asia, Europe and the Americas, we implement purchasing strategies through conferences of procurement officers and other such meetings to promote optimal procurement activities suited to each region.

Priority activities

- Establishing a framework for strengthening stable procurement

- Further strengthening the cost planning activity

- Expanding centralized purchasing

- Strengthening procurement quality control

- Strengthening a procurement platform for supporting relevant activities and measures

- Strengthening global optimal procurement

In addition to this initiative, we will also promote activities to mitigate any perceived risks regarding a range of issues related to labor practices and environmental problems in the procurement supply chain and thereby strengthen our business continuity plan (BCP).

Framework for promotion of procurement supply chain management

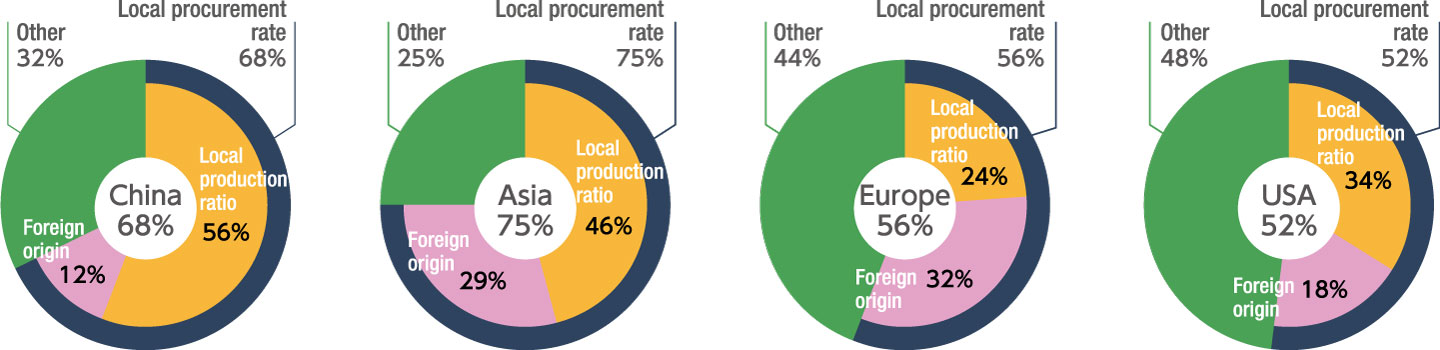

Local procurement rate in the major regions (Mitsubishi Electric Group)

- *1 Local procurement rate: Materials, parts, etc. (regardless of country of origin) that are procured by overseas production sites at their own discretion

- *2 Local production ratio: Among all locally procured items, the procurement ratio of items produced in the country of the overseas site

- *3 Foreign origin: Among all locally procured items, the procurement ratio of items produced in countries other than the country of the overseas site

Mitsubishi Electric Group Policies for Responsible Minerals Procurement

The Mitsubishi Electric Group aims for transparency in its procurement supply chain to avoid any affiliation with armed groups that trade in conflict minerals*1 as their source of funding. We also recognize the possibilities of human rights violations occurring in the severe labor conditions in cobalt mining sites as a major problem. The Group adheres to the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas*2, and removes certain minerals from the procurement supply chain in situations where their procurement encourages or contributes to serious human rights violations or environmental destruction.

- *1 Conflict minerals refers to gold, tin, tantalum, tungsten, and other minerals that have been determined by the U.S. State Department to be a source of support for armed groups when mined in the countries referred to above.

- *2

OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (PDF:1.6MB)

Report of survey results of restrictions on conflict minerals

Mitsubishi Electric takes part in the Responsible Minerals Trade Working Group of the Japan Electronics and Information Technology Industries Association (JEITA), and addresses restrictions on conflict minerals in cooperation with other industry organizations. Surveys are conducted using the survey form (the Conflict Minerals Reporting Template (CMRT)*1 or the Cobalt Reporting Template (CRT)*2) that is commonly used in the automobile, electric, and electronic industries. In fiscal 2021, surveys were carried out on 717 suppliers, and responses in survey form were obtained from 639 of these suppliers, which include 491 suppliers for which we have been able to identify all smelters. In addition to continuing to request suppliers to collect accurate information on smelting companies, various other measures will continue to be implemented in order to comply with the restrictions on conflict minerals.

- *1 Conflict Minerals Reporting Template issued by the Responsible Minerals Initiative

- *2 Cobalt Reporting Template issued by the Responsible Minerals Initiative

Number of smelting companies identified in a survey of conflict minerals and their list in FY2021 (Number of smelting companies identified: 364 companies)

(As of April 2, 2021)

| Tin | Tantalum | Tungsten | Gold |

|---|---|---|---|

| 108 companies (of which, 1 company is from an applicable country*) |

43 companies (No applicable countries) |

50 companies (No applicable countries) |

163 companies (of which, 1 company is from an applicable country) |

- * Applicable countries: A total of ten countries designated as applicable countries for conflict minerals, including the Democratic Republic of the Congo, Angola, Zambia, Tanzania, Uganda, South Sudan, Rwanda, Central African Republic, Republic of Congo, and Burundi.

Strengthening Sustainability Initiatives along the Procurement Supply Chain

Initiatives to address environmental issues

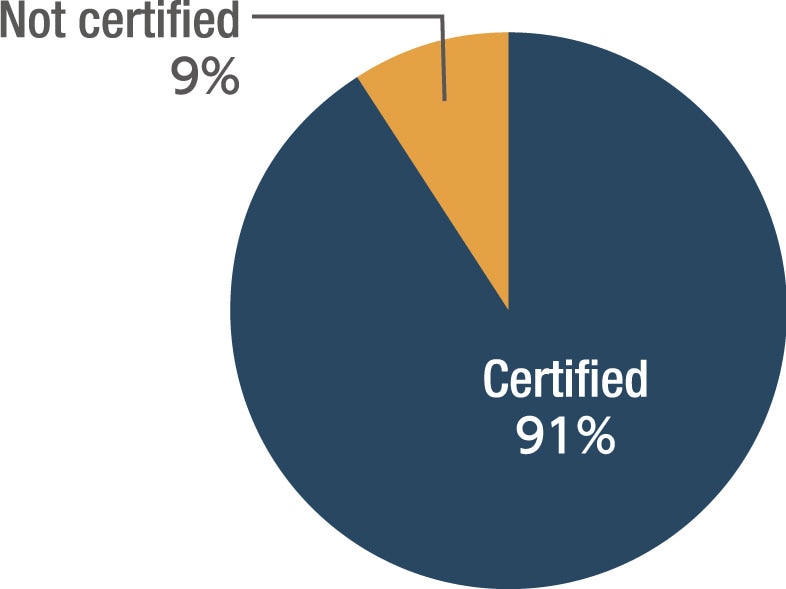

Since 2006, the Mitsubishi Electric Group has been evaluating the progress of suppliers’ initiatives to address environmental issues under the Green Accreditation System. Based on the Green Procurement Standards Guide and using an original survey form, the System involves a survey of each supplier’s progress in acquiring environmental management system certification, the supplier’s status of compliance with laws and regulations related to the environment, and its management of chemical substances contained in components and materials they deliver to our company. Under the System, suppliers who meet our standards are certified.

We ultimately minimize environmental risks by properly evaluating the progress of our suppliers’ environmental initiatives under this System, and by providing advice on any corrections that should be made by suppliers who do not meet the certification standards.

Initiatives to address social issues

From 2009, the status of sustainability initiatives has been included in the survey items, and a survey is also made of issues such as human rights, labor practices, safety and health, legal compliance, and product safety. Furthermore, the CSR Procurement Guidelines were established in 2018 based on the RBA Code of Conduct (Version 6.0) that was formulated and announced by the Responsible Business Alliance. To verify our suppliers’ commitment to promoting the content of the guidelines, a consent form is attached to the last page of the guidelines.

Note that we plan to integrate the CSR Procurement Guideline and the Green Accreditation Guideline to create the Sustainability Procurement Guidelines.

We have raised the following points as the core activity objectives of fiscal 2022.

1. Ensuring that we obtain the consent forms for the CSR Procurement Guidelines from suppliers

The Mitsubishi Electric Group is aiming to obtain the consent forms for the CSR Procurement Guidelines from all suppliers with whom we will continue to do business through the end of September 2021 (about 4,000 companies). From fiscal 2019 to 2021, we received signatures for the consent forms for the CSR Procurement Guidelines from a total of about 2,800 suppliers. We will work to obtain the forms from all suppliers that have yet to respond.

2. Continuing activities aimed at understanding and mitigating serious human rights risks in the procurement supply chain (forced labor of foreign laborers, dangerous or hazardous labor, etc.)

In addition to the investigations in progress, we have conducted a survey of 390 main subcontract factories in the Mitsubishi Electric Group’s production activity on foreign technical intern trainees in 2019. Although there were no suppliers who are at risk of infringing on the Technical Intern Training Act, we will continue promoting activities for preventing the violation of human rights of foreign technical intern trainees.

3. Building a mechanism for handling grievances for the entire procurement supply chain

We will consider enhancing the mechanism for handling grievances to receive complaints from the secondary suppliers and suppliers further down the supply chain and to resolve issues. Currently, we have the following as the points of contact for handling grievances.

4. Decarbonization in the procurement supply chain

The Environmental Sustainability Vision 2050 aims to achieve decarbonization of the entire value chain. We will grasp the level of reduction in CO2 emissions generated during production by suppliers and call for further reductions.

Requests to Suppliers

Suppliers to the Mitsubishi Electric Group are requested to gain an understanding of the Group’s Purchasing Policy and CSR Procurement Policy*, and to disseminate these policies to their supply chain. They are especially requested to thoroughly comply with the points below, which the Group has identified as priority issues to be addressed through the entire procurement supply chain. Additionally, new suppliers are asked to submit their agreement to comply with the CSR Procurement Policy and a completed survey form upon reading and understanding the guidelines.

For details, please refer to each of our guidelines (Green Procurement Standards Guide, CSR Procurement Guidelines).

- * The Mitsubishi Electric Group’s Green Procurement Standards Guide and CSR Procurement Guidelines are provided below. These documents have been revised appropriately in response to changes in laws, regulations and social norms.

Important requests to suppliers

1. Compliance with laws, regulations and social norms

Please comply with laws and regulations in countries and regions where you engage in business, as well as with international agreements, transaction ethics, and social norms.

(Elimination of corrupt practices such as bribery, embezzlement, and illegal political contributions; compliance with relevant laws and regulations, including the Antimonopoly Act, Subcontractor Act, and Foreign Exchange Act; prohibition of the illegal acquisition and utilization of intellectual property; proper information disclosure; execution of faithful transactions based on contracts, etc.)

2. Respect for human rights

Please respect basic human rights in countries and regions where you engage in business.

(Prohibition of inhumane treatment like forced labor, child labor, abusive treatment, human trafficking, and harassment; prohibition of all forms of discrimination; proper payment of wages; proper management of working hours; respect for the right to organize, etc.)

3. Consideration for health and safety

Please give due consideration to health and safety in all countries and regions where you engage in business.

(Safety measures for machines and devices; evaluation and measures against the occurrence of accident and health hazard risks; preventive measures against large-scale disasters and accidents, etc.)

4. Environmental considerations

Please take measures to provide products and services that place minimum burden on the environment.

(Acquisition, maintenance and management of environmental management system certification; compliance with environmental laws and regulations; proper management of chemical substances in products, etc.)

5. Product and service quality and safety

Please take measures to ensure the quality and safety of products and services you provide.

(Design, evaluation and testing for ensuring safety; compliance with laws and regulations related to safety; construction, maintenance and management of quality management systems, etc.)

6. Security measures for information systems

Please take appropriate measures to protect against computer network threats.

(Construction of prevention measures against computer viruses and cyberattacks; prevention of information leakage through proper management of confidential information and personal information, etc.)

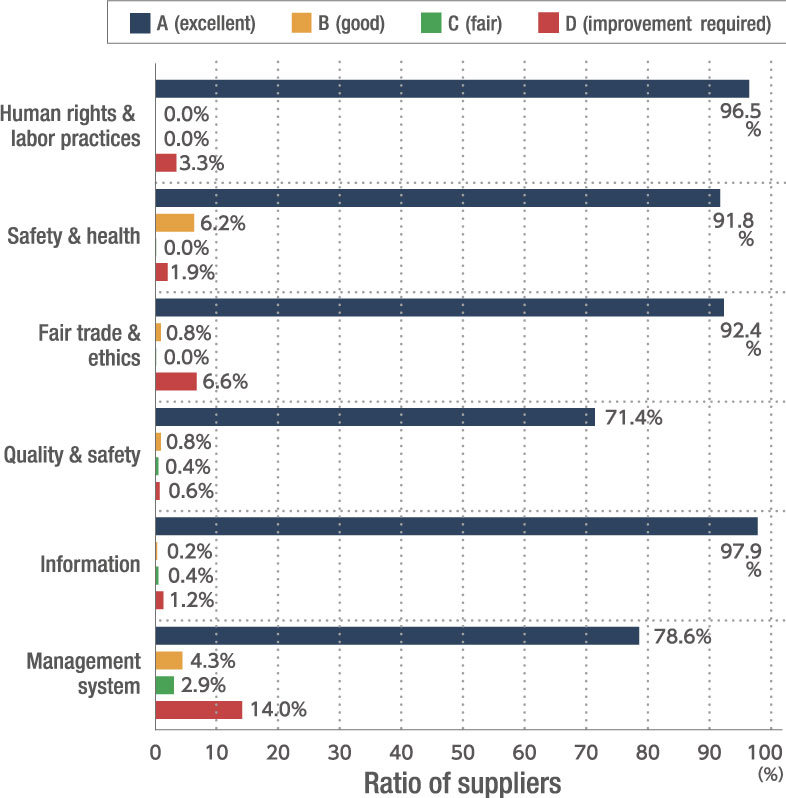

Evaluation Status of Suppliers' Initiatives to Address Sustainability Issues

Basic policy of supplier surveys

The Mitsubishi Electric Group verifies the progress of suppliers’ initiatives to respond to the requirements outlined in the Green Procurement Standards Guide and CSR Procurement Guidelines by requesting principal suppliers who fall within the top 80% in terms of purchase amounts to complete a survey form (prior to commencing transactions in the case of new transactions and at certain intervals in the case of ongoing transactions (every three years, as a rule)). In response to our suppliers’ replies to these surveys, we provide feedback about the results of the evaluation. We also communicate with suppliers who have scored low in any one of the survey items, to request the necessary corrections. This is done through individual meetings and other such means. The survey form has been revised in 2018 following the formulation of the CSR Procurement Guidelines.

Activity results

From 2006, the evaluation covered domestic suppliers only. However, the range was expanded in fiscal 2018 to include overseas suppliers also. The fiscal 2018 survey placed priority on the China and Thailand region, but from fiscal 2019, we extended survey implementation to Europe and the U.S.

Responses to the Green Accreditation/CSR Procurement survey form (Mitsubishi Electric)

(As of April 7, 2021)

| FY 2018 | FY 2019 | FY 2020 | FY 2021 | |

|---|---|---|---|---|

| Existing suppliers | 696 | 1,201 | 455 | 511* |

| New suppliers | 25 | 60 | 97 | 69 |

| Response rate | 99% | 96% | 82% | 88% |

- 1 Total number of suppliers: Approx. 10,000 companies (includes about 2,500 suppliers that were among the top 80% of purchases)

- 2 We conducted surveys for all of the above suppliers (about 2,500 companies) in the three-year period between 2017 and 2019.

- 3 The above figures include the cases where the companies resubmitted their survey response after receiving the improvement instructions.

- * The above figures include 74 companies who were surveyed in fiscal 2020 and failed to pass the criteria or have not responded to the survey. The Mitsubishi Electric Group suspended transactions with 5 companies who have yet to gain Green Accreditation among the supplies surveyed in fiscal 2020. The breakdown of these 5 companies is as follows: 2 failed to pass the Green Accreditation criteria, 1 needed to correct their CSR activities, and 2 failed to respond.

Responses to the Green Accreditation/CSR Procurement survey form (domestic and overseas affiliated companies of Mitsubishi Electric)

(As of April 7, 2021)

| FY 2018 | FY 2019 | FY 2020 | FY 2021 | |

|---|---|---|---|---|

| Surveyed suppliers | 1,378 | 595 | 1,169 | 1,080 |

| Response rate | 94% | 60.5% | 74% | 71% |

Signatures for the CSR Procurement Guidelines consent forms in FY 2021

(As of April 7, 2021)

| Mitsubishi Electric | Domestic and overseas affiliated companies | |

|---|---|---|

| Requested companies | 639 companies | 2,469 companies |

| Responses received (rate)* | 570 companies(89%) | 2,031 companies (82%) |

- * The rate calculated using the number of requested companies as the denominator.

-

FY 2021 rate of green accreditation certification among suppliers (Mitsubishi Electric)

-

FY 2021 results of green accreditation and CSR procurement surveys among suppliers (Mitsubishi Electric)

Number of suppliers given guidance in fiscal 2021 and the content of the guidance (Mitsubishi Electric)

(As of April 12, 2021)

| Item | No. of companies given guidance |

No. of completions | Content of guidance |

|---|---|---|---|

| Environment | 64 | 24 | Strengthening of management of chemical substances in products (creation of management regulations and understanding chemical substances in products) |

| Human rights, labor practices, safety and health | 96 | 26 | Encouraging secondary suppliers to take up sustainability practices |

-

Providing safety guidance during an onsite inspection of a supplier's company (overseas)

-

Survey on Foreign Technical Intern Trainees

Mitsubishi Electric conducted a survey of 390 main subcontract factories in the Mitsubishi Electric Group’s production activity on foreign technical intern trainees and obtained responses from all the companies surveyed. Among the companies surveyed, 136 companies hire technical intern trainees, and we confirmed with the suppliers as to whether they are "excellent implementing organizations*" and the presence or absence of risks associated with implementing training (50 suppliers have been accredited as "excellent implementing organizations"). As a result of the survey, it was found that 24 out of 86 companies who have not been accredited as "excellent implementing organizations" are required to make improvements. However, there were no suppliers who do not observe the Technical Intern Training Act, the Labor Standards Law, etc.

We will provide guidance on items to be improved as well as continue promoting activities for preventing the violation of human rights of foreign technical intern trainees.

- * An accreditation system administered by the Organization for Technical Intern Training (OTIT). A total score for a track record of acquiring the skills, the acceptance system, employment conditions of technical intern trainees, presence or absence of violations of laws and regulations, and consultation and support system for technical intern trainees of at least 60% of the full marks conforms to the criteria for the excellent implementing organizations. When a company is accredited as an excellent implementing organization, the intern training period is extended and the quota for the number of trainees accepted is increased.

| Matters to be improved | No. of companies (may be duplicated) |

|---|---|

| A procedure or mechanism for "accepting requests" and "considering taking measures" for cases where special facilities must be provided for religious reasons (worship, meals, etc.) is absent | 9 |

| Important indications for safety and health, such as dangerous goods labels and the display of evacuation routes, are not displayed in languages understood by technical intern trainees | 17 |

| Matters supervised by the supervising organization are not recorded or saved | 5 |

| A mechanism for internal or external whistleblowing has not been built | 2 |

-

Guidance on multilingualization of dangerous materials (Gunma Works)

-

Doorways and evacuation routes (Gunma Works)

Communication with Suppliers

At each office, the Mitsubishi Electric Group holds seminars that disseminate a full understanding of the Group's Purchasing Policy and CSR Procurement Policy among suppliers. In order to gain the approval of suppliers to the Mitsubishi Group’s policies as demonstrated through these activities, we hold regular exchanges of views with our suppliers based on their responses to our Supplier Surveys. Suppliers are asked to further strengthen sustainability initiatives at their companies as well. In fiscal 2021, we refrained from holding any large seminars to prevent the spread of COVID-19. Instead, we are holding online seminars using Microsoft Teams.

We will continue to conduct support activities for Business Continuity Planning (BCP)*, as well as holding a variety of seminars, including those about changes in chemical substance restrictions such as the EU RoHS Directive, and programs about compliance (including export control, information security and management, the Subcontract Act, etc.).

- * BCP (business continuity planning): Being prepared for any disaster or other emergency situation by planning how to minimize damage to the company and how to continue or restore business activities.

Strengthening Partnerships with Suppliers

Award given by Mitsubishi Electric executives (Inazawa Building Systems Works)

The Mitsubishi Electric Group engages in joint-development from the initial stages to the development of parts and materials, and works in partnership with suppliers to engage in Value Engineering (VE) activities with the aim of adopting advanced products, recycling resources, and reducing the consumption of materials.

Through these activities, we reduce the input of materials and minimize environmental burden by making products more compact and lightweight, and build a win-win relationship that leads to increased sales and enhanced technology capabilities for both Mitsubishi Electric and our partners. We also give awards to suppliers whose achievements are especially significant.

Mitsubishi Electric proactively conducts this activity to suppliers not only in Japan but also overseas, including in the UK, US, China, Thailand, Indonesia, Mexico, India, and Colombia. We also promote internal and external human resource development, such as by conferring an instructor's certificate on those who have taken a written test and participated in the VE program in VE lectures, and demonstrate a certain level of knowledge.

-

VE lecture in the Southeast Asia region (Indonesia)

-

VE lecture in the Southeast Asia region (India)

-

Presenting an award to a supplier

in the Southeast Asia region (Malaysia) -

Meeting with a supplier in the China region

Providing Learning Programs on Procurement Laws and Regulations

The Mitsubishi Electric Group offers various learning programs on laws and regulations related to the operations of employees in charge of procurement activities. In Japan for example, our course on materials procurement laws provides guidance and education for thorough compliance with laws and regulations that particularly pertain to procurement activities, such as the Anti-Monopoly Act, the Act against Delay in Payment of Subcontract Proceeds, Etc. to Subcontractors, and the Construction Contractors Law. Guidance and education are also provided overseas. Based on the Code of Conduct and check sheets, learning programs strictly teach employees not to become involved in bribery, embezzlement, or any other form of action that goes against the principle of fair trade. Compliance education related to procurement is also held for local employees in charge of procurement operations overseas.

To further strengthen CSR initiatives (particularly along our procurement supply chain), we are making greater efforts to share information on activities implemented by each office as well as instructional information, such as by holding Review Meetings for CSR Promotion in the Supply Chain and providing CSR education to employees in procurement departments.

-

Compliance education related to procurement in the Thailand region

-

Review Meeting for CSR Promotion in the Supply Chain